SALIENT FEATURES

- Applicable to all ranges of Hydraulic Equipments

- Maintenance free, quick and easy to assemble, just fix the screw on the shaft.

- Special modifications to customers’ requirement.

- Lengthen or shorten or key way bore of hubs available.

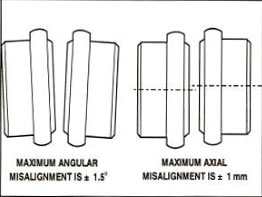

- Permits angular, parallel and axial offset.

- Wide accurately machine surface offer easy visual alignment.

- Sleeve made of high graded nylon material, resistance to all hydraulic fluids.

- Concentricity within 0.0008 inches assures centrifular and dynamic balance, important at high speed.

- Entire ranges of coupling are available from 0.5H.P to 75 H.P suitable for shaft size 14mm to 65mm in diameter.

- High degree of factor of safety.

HOW TO SELECT YOUR COUPLINGS ?

The following informations are given to select the right coupling to suit your allplications.

- Find your load characteristics based on the driven unitused

- Use the load characteristic to determine its service factor (F)

- Refer to torque and horse power capacity at varying speeds (RPM) and shaft size to suit the maximum bore size of the the gear hub recommended.

RATING OF COUPLING = (H.P of application x 100 x F) / (RPM of application)

SERVICE FACTOR (F)

| APPLICATION | ELECTRIC MOTORS | PETROL / DIESEL ENGINE |

| Uniform Load Light Load (L) Medium Load (M)

Heavy Load (H) |

1.00

1.25 1.75 |

1.20

1.50 2.00 |

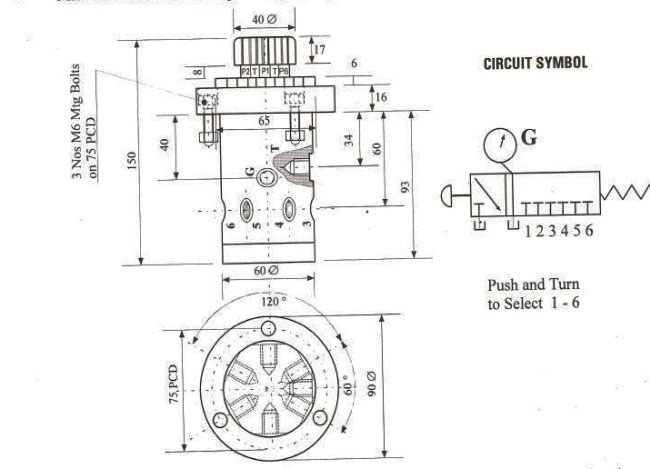

GAUGE ISOLATOR VALVE (6 STATION)

MODEL – 6S – GIV – PR

The 6 Station units is designed for panel mounting and is a highly compact unit which saves panel space by reducing number of pressure gauges. Only one common gauge is required to read different 6 system pressures. This unit is very much useful where more than one gauge reading is required and if any of six stations is not being used plug the unused ports. If three ports are used plug No. 1.3 and 5 ports to balance the valve dynamically.

OPERATION:

- Turn the Knob for selecting the pressure port and push to read the pressure. In normal condition gauge is vented tank.

SPECIFICATON:

- All ports 1/4 “BSP high graded cast Iron Body.

- Maximum working pressure 3000 P.S.I

- Maximum allowable leakage through tank port 3 to 4 CC per minute at 3000 P.S.I.